Understanding the 2005 Dodge Cummins ECM wiring diagram is a crucial step for any owner looking to dive deeper into the intricate workings of their beloved truck. Whether you're a seasoned mechanic or a DIY enthusiast, this diagram acts as your roadmap, guiding you through the complex electrical pathways that control the heart of your Cummins engine. Having a solid grasp of the 2005 Dodge Cummins ECM wiring diagram can be the key to troubleshooting issues, performing upgrades, and ensuring optimal performance.

What Exactly is a 2005 Dodge Cummins ECM Wiring Diagram and Why You Need One

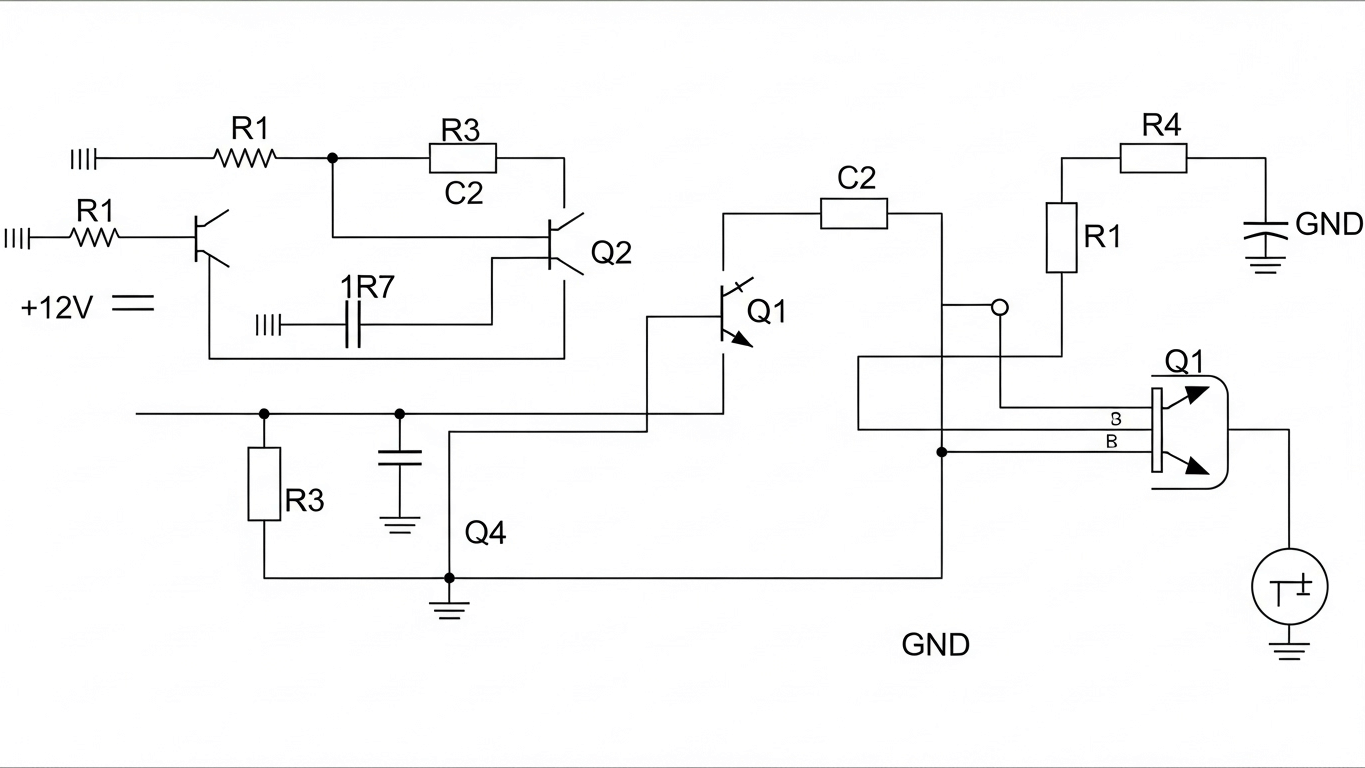

At its core, a 2005 Dodge Cummins ECM wiring diagram is a visual representation of all the electrical connections between your Engine Control Module (ECM) – the brain of your engine – and the various sensors, actuators, and other components it communicates with. Think of it as a blueprint that shows how electricity flows to and from the ECM, detailing each wire's color, its destination, and its specific function. This diagram is indispensable when diagnosing problems. For instance, if your check engine light illuminates, the wiring diagram can help you pinpoint which sensor might be malfunctioning by tracing the circuit. It’s also invaluable for understanding how aftermarket performance modules or accessories integrate with your truck’s existing electrical system. The importance of having an accurate and detailed 2005 Dodge Cummins ECM wiring diagram cannot be overstated for anyone serious about maintaining or modifying their vehicle.

Here's a breakdown of what you'll typically find on a 2005 Dodge Cummins ECM wiring diagram:

- ECM Pinouts: A detailed list or diagram showing each pin on the ECM connector and what signal or power source it's responsible for.

- Wire Colors and Gauges: Essential for identifying specific circuits, as manufacturers use standardized color codes for wiring.

- Component Locations: Often, diagrams will indicate where key components like sensors, solenoids, and relays are physically located on the engine or chassis.

- Circuit Descriptions: Explanations of what each circuit does, such as the fuel injector circuit, the crank position sensor circuit, or the EGR control circuit.

These diagrams are used in a variety of scenarios:

- Troubleshooting: When a specific engine performance issue arises, like rough idling or poor acceleration, the diagram helps technicians trace the faulty circuit.

- Installation of Aftermarket Parts: Upgrading injectors, turbochargers, or adding performance tuners often requires understanding how to tap into or modify existing wiring.

- Repair and Replacement: If a sensor or actuator fails, the diagram guides the technician in locating and disconnecting the correct wires for replacement.

- Custom Wiring Projects: For those undertaking unique modifications, the diagram serves as the foundational guide for creating new electrical pathways.

Let's look at a simplified example of how different systems are represented:

| System | ECM Connection | Function |

|---|---|---|

| Crankshaft Position Sensor | Pin X (e.g., Yellow wire) | Measures engine speed and position |

| Fuel Injector #1 | Pin Y (e.g., Blue wire) | Controls fuel delivery to cylinder 1 |

| Mass Air Flow Sensor | Pin Z (e.g., Red wire) | Measures incoming air density |

To gain a comprehensive understanding and to effectively utilize this vital information for your 2005 Dodge Cummins, we highly recommend referring to the detailed resources available in the section that follows this article. These resources provide the exact specifications you need for your truck.